Today, the rugged reliability of military specifications, specifically MIL-DTL-5015 series and MIL-DTL-26482 series, has become the gold standard for defence, aviation, railways, heavy engineering, and factory automation from Berlin to Bangalore.

For a design engineer in Italy or a procurement manager in Canada, the challenge isn’t just choosing the right connector but also sourcing it efficiently. In a post-pandemic world, relying on a single major OEM often leads to long lead times, high Minimum Order Quantities (MOQs), and potential production disruptions that could cost millions of dollars.

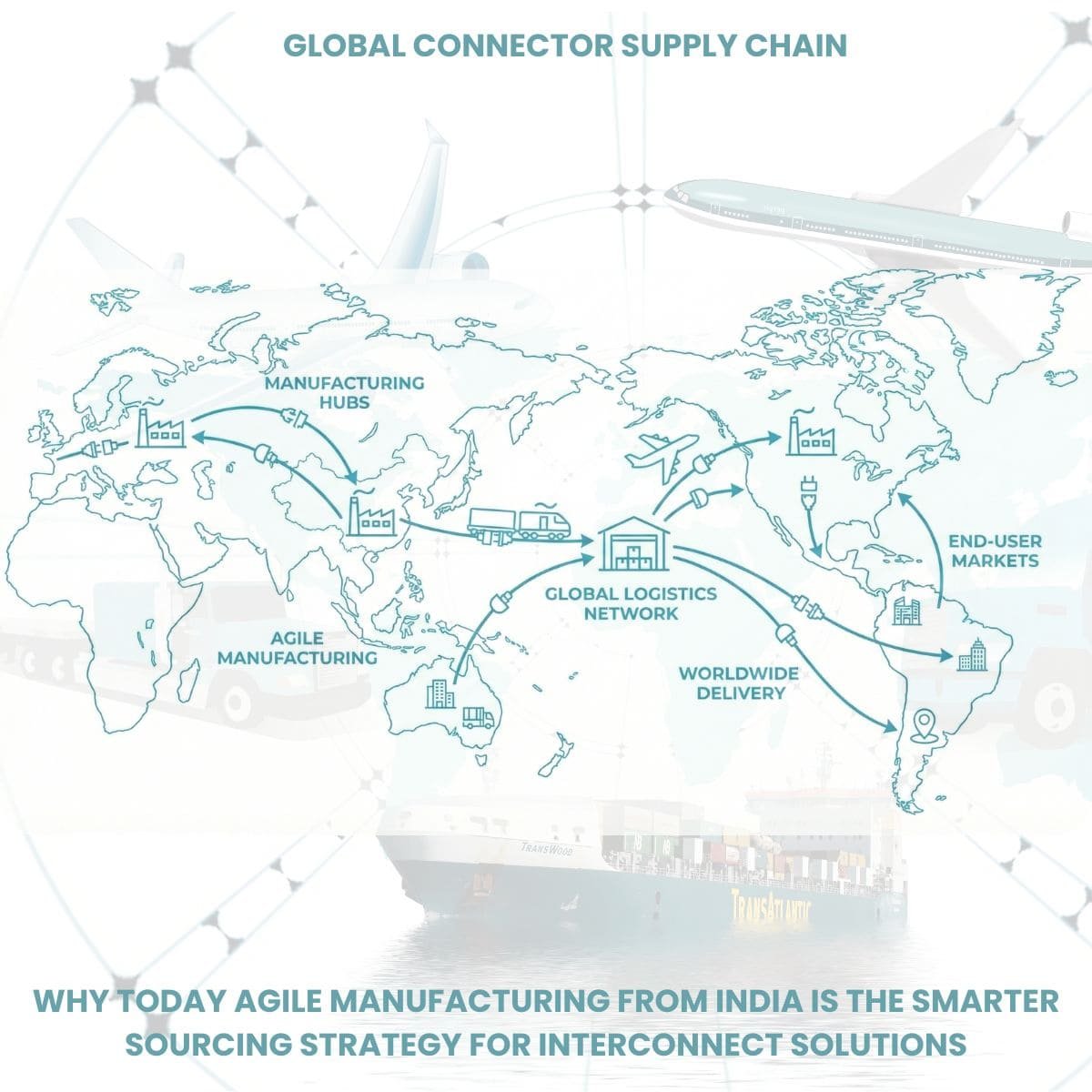

This guide breaks down the “Big Three” circular connectors and explains why Agile Manufacturing from India is the smarter sourcing strategy for the global market –

Part 1: The “Big Three” MIL-Specs Explained

Understanding the distinct strengths of these three standards is critical for selecting the right interface for your application.

1. MIL-DTL-5015: The Heavy-Duty Workhorse

- Best For: High Power, Heavy Machinery, Locomotives, Defence

- The Design: Known for its threaded coupling, bayonet and robust shell. It is the legacy standard for delivering high amperage in rough environments where weight is not the primary concern.

- Global Application: Widely used in Mass Transit (traction motors) and industrial power distribution across Europe, North America and Asia.

2. MIL-DTL-26482 Series 1: The Compact All-Rounder

- Best For: Industrial Automation, Telecommunications, Sensors.

- The Design: A medium-density connector featuring a 3-point bayonet lock for quick disconnects. It creates a secure, vibration-proof seal with a simple quarter-turn.

- Global Application: The standard choice for robotic arms and outdoor instrumentation where moisture resistance (IP67) is non-negotiable.

3. MIL-DTL-38999: The High-Performance Shield

- Best For: Aerospace, Avionics, Advanced Defence Systems.

- The Design: The highest density of the three. It features “scoop-proof” designs to prevent pin damage and 360-degree shielding fingers for superior Electromagnetic Interference (EMI) protection.

- Global Application: Essential for modern defense electronics and commercial avionics where signal integrity is paramount.

Part 2: The Global Sourcing Crisis

Sourcing these components worldwide often involves navigating a complex landscape of rigid giants and geopolitical risks.

Large manufacturers, although they produce excellent quality, their production is built on mass volume.

- The Problem: If you need a custom backshell or a specific plating (like Cadmium or Black Zinc Nickel) for a pilot run of 50 units, you may face lead times of nearly a year.

- The Risk: High MOQs and long lead times often force SMEs to over-order, tying up capital in inventory.

- The Need for Supply Chain Diversification –Relying on a single region for manufacturing is a risk. Global companies are actively seeking “China Plus One” strategies or alternative hubs to insulate their projects from logistics disruptions and tariffs.

As a result, India has emerged as a preferred manufacturing hub for high-precision engineering components, offering a stable political climate and skilled technical labour.

Part 3: The Agile Manufacturing Advantage

Why Agile Manufacturing Matters:

- Speed Over Bureaucracy: Global giants have rigid production queues. Agile manufacturer can retool and prioritise urgent orders. Whether the final assembly is in Europe or the US, responsive set-ups can often manufacture and ship custom prototypes in weeks, not months.

- Customization is the Standard: Need a specific insert rotation or a non-standard backshell for a tight space? A custom cable harness? Nimble manufacturing shopfloors can incorporate them in-house and don’t need to “request a quote from headquarters”.

- Cost-Effective Quality: By leveraging Indian manufacturing efficiencies, agile manufacturers provide Mil-Spec performance at a significantly more competitive price without the quality fade often associated with low-cost regions.

At Jetronics India, we don’t just sell connectors; we manufacture interconnect solutions for the world. We operate on an Agile Manufacturing model designed to solve the pain points of global engineers.

Ready to Diversify Your Supply Chain?

We manufacture a fully intermateable equivalent to the MIL-DTL-5015 and MIL-DTL-26482 Series. This ensures global compatibility with zero compromise on durability. We also manufacture a precision-engineered equivalent to the Series. By manufacturing in India, we offer custom shell platings and insert arrangements that global catalogues often mark as “non-stock.”

Stop waiting 30 weeks for a standard part. Choose a manufacturing partner that moves at the speed of your project, anywhere in the world.